Laser laser la laser, ho hloekisa, ho hlatsoa le ho tšoaea mechini e tšoaeang

Fumana qotsulo

Lihlahisoa

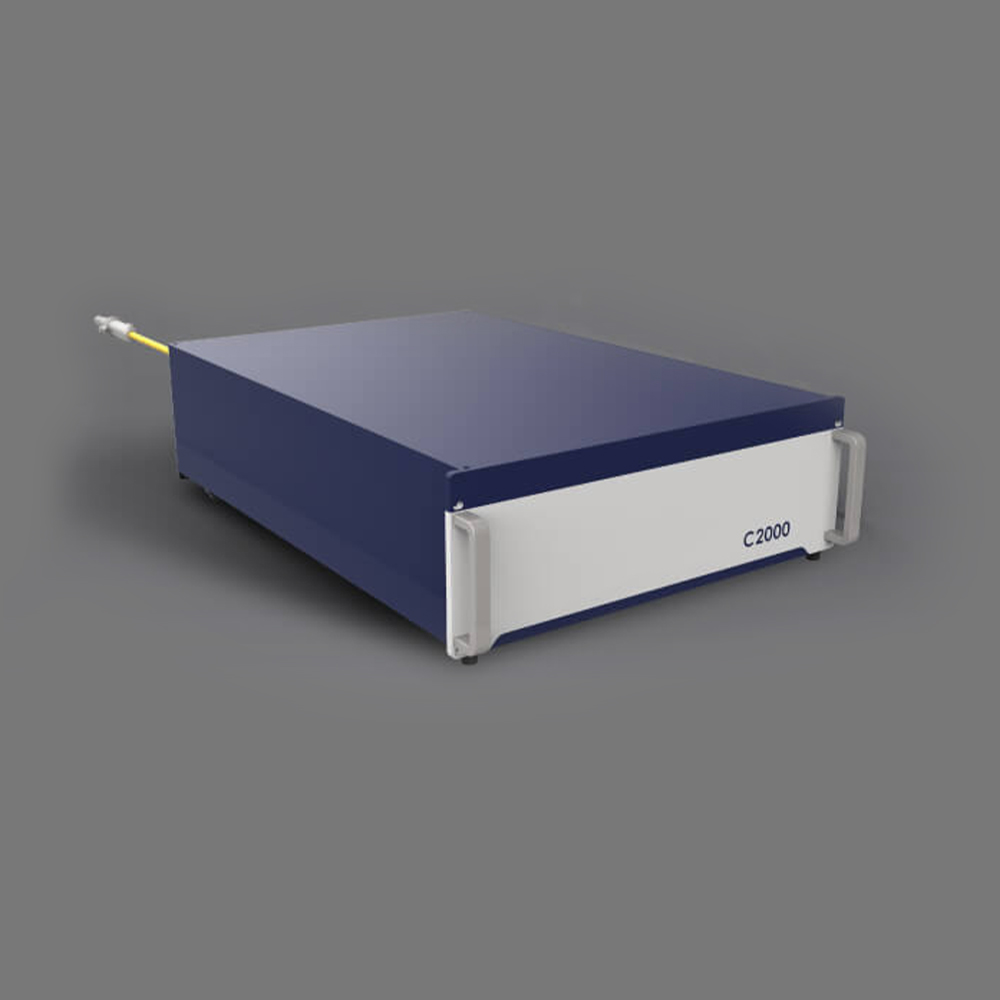

1000W 1500W ea 2000W ea 2000W ea hau ea WASHeding mochini oa letsoho

Tlhaloso ea Sehlahisoa

Machine ea welding ea chuke Laser e ka baka litselana tse sa feleng ka katleho e ntle ea katleho le manonyeletso a tiileng a phahame ho feta mochini o tloaelehileng o tloaelehileng. Bareki ba rona ba ka rua molemo ka ho tsoelang pele ho mongobo, ho boreleli ebile ho se na mekhoa e latelang ea Poshing.

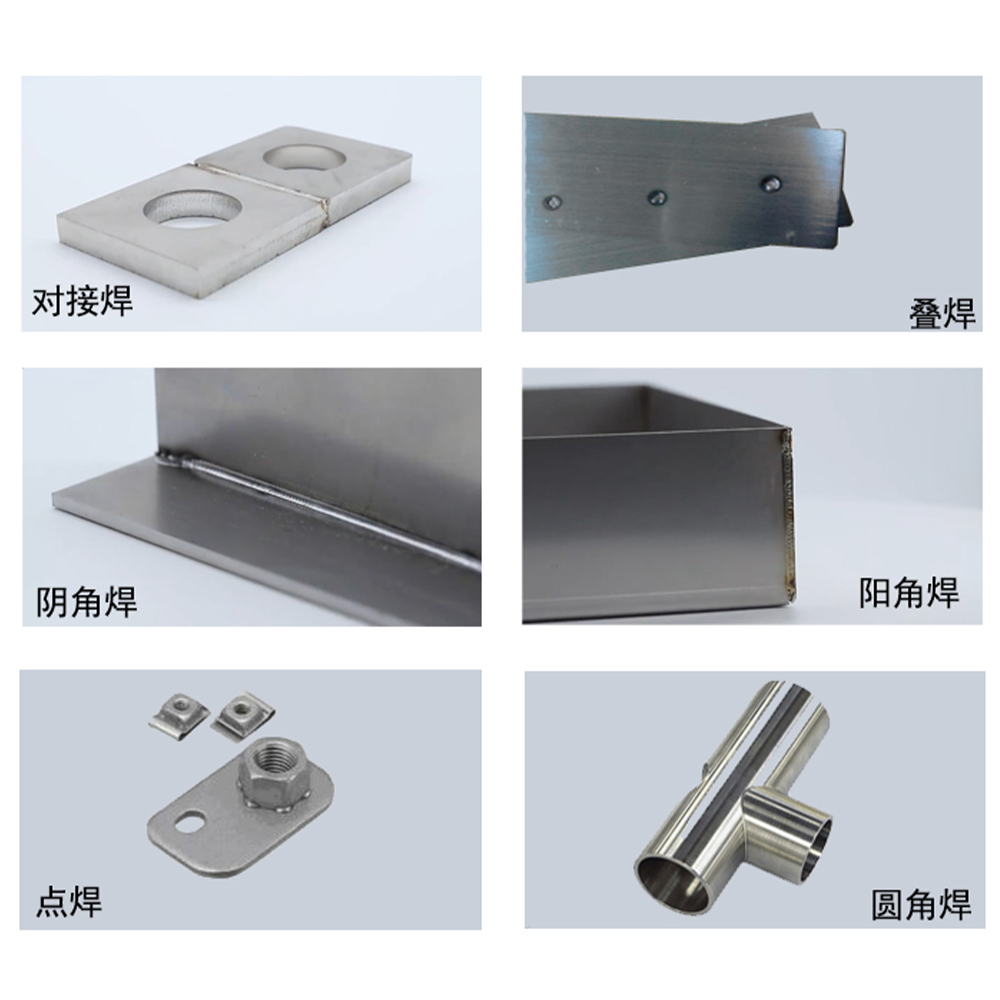

Mochini oa li-cuke Laser o ka fana ka mekhoa e mengata ea mangata ho rarolla mathata a hau a ho palama. Ho senyeha ha eona ho se ho fetile habonolo habonolo. Li-nozzles tse neng li jelletse li-nozzles tse fapaneng li ka u thusa ka mekhoa e mengata, joalo ka welding, e fetang boima E etsang ho etsa hore likepe tsa hau tse rarahaneng kapa libopeho tse sa tloaelehang tsa libopeho li fetoha tse bonolo.

Machine ea welding ea chuke Laser e ka baka litselana tse sa feleng ka katleho e ntle ea katleho le manonyeletso a tiileng a phahame ho feta mochini o tloaelehileng o tloaelehileng. Bareki ba rona ba ka rua molemo ka ho tsoelang pele ho mongobo, ho boreleli ebile ho se na mekhoa e latelang ea Poshing.

Chuke Handheld Laser mochini oa welsing o hloka mokhoa o moholo, ona o bonolo o boloka litšenyehelo tsa basebetsi bakeng sa bareki ba rona.

Litlhaloso

| Lintlha tsa botekgeniki | |

| Lebitso | Mochini oa weld oa laser |

| Mofuta oa diaparo | Fiber |

| Wavelength | 1064nm |

| Matla | 1000wn / 1500w / 2000W |

| Khafetsa | 20-500khkhz |

| Bolelele ba 'nete | 120mm |

| Mokhoa oa ho futhumatsa | Ho futhumala ha metsi |

| Bolelele ba fiber | 5m / 10m / 15m |

| Kou | QBH |

| Sebetsa Matla | ≤6kw |

| Tlhokahalo ea Khatello ea Moea | 4-6 Bar |

| Tlhokahalo ea Motlakase | 1kw / 1.5kw-ac380v / 50 / 60hz 2kw-ac380v / 50 / 60hz |

| Dia of wineding terata ea welding | 0.1-2.0mmmm |

| Thabo ea Hunese | ≤20s |

| Felaft frequency | ≤50hz |

WAser Wording ke mokhoa oo khanya e sa sebetsoeng, le ka mor'a ts'ebetso e sa koaheloang ke thepa e tlamehang ho etsa khokahano e sa feleng.

Likarolo tse nkuoeng li sebelisoa haholo likarolo tse kholo le tse mahareng tsa pampiri, mabokose a mantlha le li-aluel listen le tse kholo tsa sehlahisoa. . E sebelisoa haholo ka kichineng le indasteri ea kamore ea ho hlapela, indasteri ea lebala la sesole le se nang leeme, lebaleng la ntlafatso ea lehae, lefapha la likoloi, jj.

Tlhahisoleseling ea Tlhahisoleseling

Lihlooho tse sa hlakang

Oha e hahiloeng butle-butle-auxis

Sistimi e matla e sebetsang

Sesebelisoa se bonolo le se hlakileng sa ho hlaka se bonolo ho tseba le ho tloaela

Digital pontsho ea skrineng ea nakoana ea data

Boemo bo phahameng ba ho soma ha lifoto tse phahameng

Sistimi ea li-fiber tsa motlakase ea bobeli fiber ea fiber e ntle le e tsitsitseng ea beam

Li-chiller tse matla

Fana ka tšireletso ea laser bakeng sa laser le Laser, netefatsa botsitso ba ts'ebetso ea tlhahiso le ho lelefatsa bophelo ba tšebeletso

Mochini oa rona oa Wels oa laser o sebetsa ebile o na le mocheso o fokolang oa sebaka sa Welding, setaea se setle sa leoatleng ebe o boloka sebopeho se tsitsitseng. Ke khetho e ntle haholo ea butt, e thata, e leng ho bokella ha mefokolo ea kahare, letheba le kenang.