Laser laser la laser, ho hloekisa, ho hlatsoa le ho tšoaea mechini e tšoaeang

Fumana qotsulo

Lihlahisoa

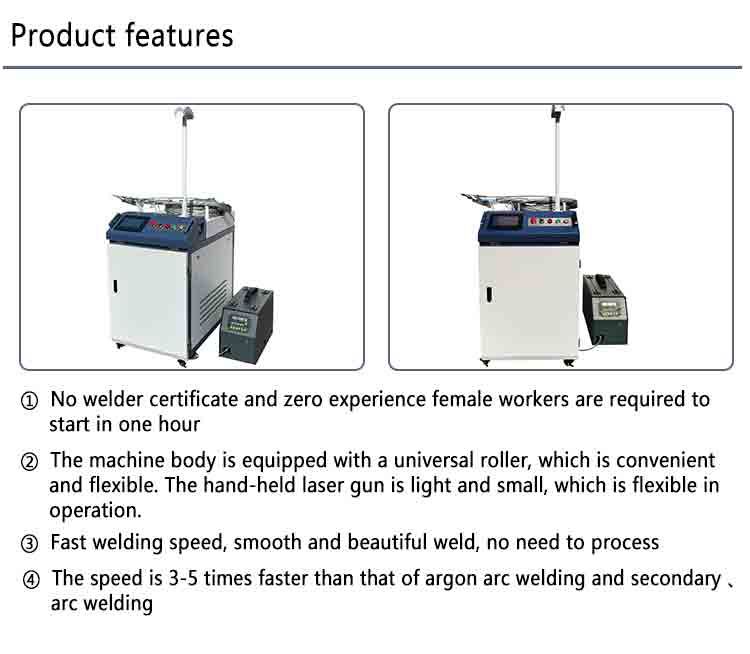

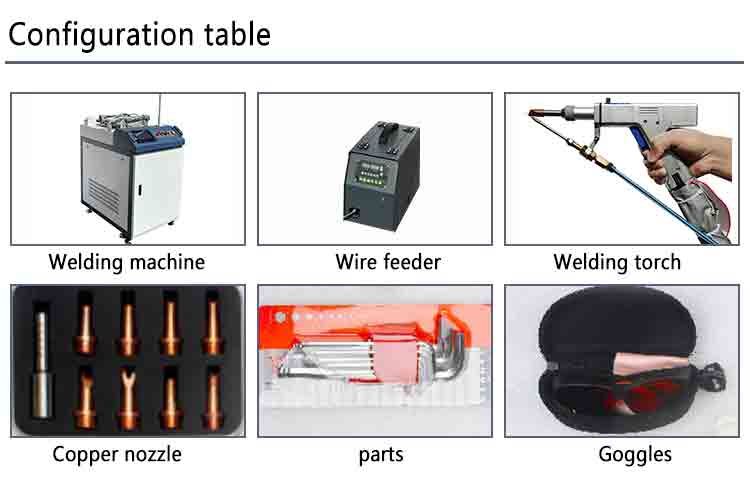

Fiber laser mochini oa welding

Lilemong tsa morao-rao, ho na le mechine e mentseng ea fiber laser e hlahile e le tsoelo-pele e kholo ea theknoloji tšimong ea Welding. Fiber Laser Mechine ea West Laser e feto-fetola indasteri ea mapheo ka tšitiso ea bona e phahameng, e leng katleho le ho tsebahala. Sengoliloeng sena se ikemiselitse ho bonts'a likarolo tsa sehlooho le melemo ea metjeko ea FAZER LAER.

Tsela e ntle haholo: e 'ngoe ea melemo ea weging ea Fer ea laser ea tsona e ikhethile. Mechine ena e sebelisa lesela le phahameng le phahameng ho theha tšenyo e moqotetsane le e tebileng e nang le tlhahiso e nyane ea mocheso. Seaparo se tsepamisitsoeng laser se lumella taolo e hlakileng ea ts'ebetso ea ho bo bona, e bakoang ke likhoka tse phahameng tse nang le likhohlano tse fokolang. Tlhaloso ena e bohlokoa haholo ho indasteri e sa batleng lethathamo le thata, joalo ka elektroniki, likoloi le aerospace.

NTOANG Ts'ebetso: Finder Mechine ea West Laser e tsebahala ka katleho ea tsona e ikhethang. Mechine ena e sebelisa theknoloji ea fiber ea sefahleho ho ea lopolla maballo a laser, a netefatsa mohloli o tsitsitseng le o shebileng. Sena se nolofalletsa lebelo le boima la ho palama ha le ntse le boloka taolo e nepahetseng holim'a ts'ebetso e ngata. Bokhoni ba ho lebala ka lebelo le phahameng ba eketsa tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso. Ho feta moo, ho kenya maikutlo a fokolang le taolo e hlakileng ea laser ho fokotsa tlhoko ea ts'ebetso ea ka morao-rao, ts'ebetso e eketsehileng e ntseng e eketseha.

Ho sitima: Monyetla o mong o moholo oa mechini ea ho se tšepane e silafatsa tlhaho ea bona. Ba khona ho lula ba mefuta-futa ea mefuta e mengata, ho kenyelletsa le tšepe e fapaneng, aluminium, koporo esita le litloaelo tsa ho se tšepahale. Hore na thepa e teteaneng kapa e teteaneng, metjeko ea wels laser e fana ka lits'oants'o tse sa fetoheng le tse tšepahalang. Ho feta moo, mochini ona o ka sebelisoa likopo tse fapaneng tsa tšepe ho tloha lits'ebetsong tsa tšepe tsa laet ho ea ho Moeli oa Leqepheng, ho etsa hore li be le liindasteri le lits'ebeletso tse fapaneng.

Tšitiso e Ntlafetseng ea Ts'ireletso le Tiiso: Mechini ea Wind ea Fiaser o ntlafalitse ba li bapisoa le mekhoa ea ho soma ha mekhoa e meholo. Hobane ba sebelisa lesela la laser laser, menyetla ea ho pepesetsoa mosi o motšo le mahlaseli a kotsi o fokotsehile haholo. Ntle le moo, ho holisa likhase tse kotsi le ho sebelisa matla a motlakase ho fokotsa tikoloho e sireletsehileng le e botala.

Qetellong: Mechini ea Winds ea fiber laser o fetotse indasteri ea manganga ka ho fana ka sepheo se phahameng, mokhoa oa ho feto-fetoha le polokeho. Mechine ena e se e le lisebelisoa tsa bohlokoa indastering ea bohlokoa, tsa thusa ho hlahisa boima bo phahameng ba boleng ba ho fana ka tlhahiso le ho fokotsa litšenyehelo. Haholo-holo theknoloji e ntse e tsoela pele, ho ka etsahala hore ebe mechini ea West Laser e tla etsa karolo ea bohlokoa ho ea ho ho hlatsoa bokamoso ba indasteri ea liteishene.