Laser laser la laser, ho hloekisa, ho hlatsoa le ho tšoaea mechini e tšoaeang

Fumana qotsulo

Lihlahisoa

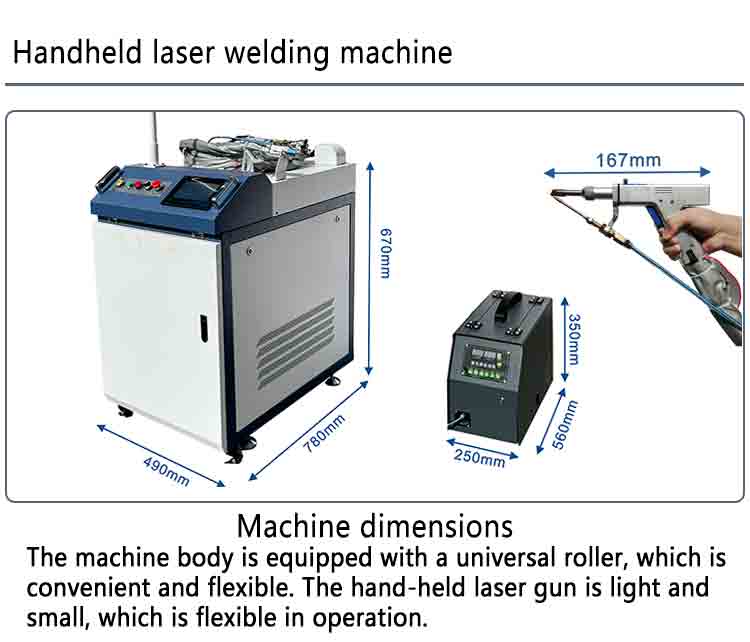

Handheld laser welder

Ha theknoloji e tsoelang pele ea mahlale le theknoloji, e fetohile theknoloji ea bohlokoa tšimong ea Warting. Le theknoloji e ncha e lebaleng la liqhobosheane tsa letsoho la laser sa lesding, e handheld laser, e handing e hohela ka mokhoa o phallang. Handheld Laser Werlder ke sesebelisoa se ntlafalitsoeng se fokotsa bonolo le ho feto-fetoha le maemo a lalo.

Lisebelisoa tsa Willi tsa Laser tsa Letšoao la Laser hangata li le boima ebile li hloka ho lokisoa maemong a itseng. Sesebelisoa sa mofuta ona se loketse merero e meholo ea boenjiniere, empa ha e matlafale ho lekaneng bakeng sa mesebetsi e itseng e nyane le e rarahaneng. Ho hlaha ha li-welders tsa Handheld Laser ho fetotse boemo bona ka botlalo. Lenane Laser Werger e nyane ebile e bobebe, e bonolo ho e sebelisa, 'me e ka tsamaea ka bolokolohi sebakeng se senyenyane. Sena se nolofalletsa letsoho la Handheld Laser ho sebelisoa masimong a mangata 'me u kopane le litlhoko tse ngata.

Likarolo tsa mantlha tsa letsoho la letsoho la letsoho la letsoho la letsoho le ntse le tsoela pele haholo, ho sebetsa hantle le tokoloho e phahameng ea ho tsamaea. E sebelisa theknoloji ea phetisetso e tsoetsoeng pele, e ka fetisellang borashe ka fiber, e arolang lesela la laser ea laser ho tsoa ho opareiti. Sena ha se sa felise polokeho ea opareishene, empa hape e fana ka maemo a mangata. Ntle le moo, handheld Laser Werld e na le ts'ebetso e makatsang e nang le ts'ebetso e ntle haholo. E ka 'na ea ka' na ea likarolo tse nyane, tse joalo ka metsoako ea elektroniki, Lisebelisoa tsa bongaka, tseo ho ntlafatsang ho nepahala le matla a ho fokola haholo. Ka nako e ts'oanang, letsoho la letsoho la letsoho le boetse le na le litšobotsi tsa katleho e phahameng, lebelo le boima la mocheso, sebaka se senyenyane se atisitsoeng ka mocheso le ho fokotsa lits'oenyeho tsa nama.

Handheld Laser Welders e sebelisoa haholo masimong a fapaneng. Ha e etsa tlhahiso, li-handheld laser li ka sebelisoa likarolo tsa makoloi, likarolo tsa aerospace, le tse ling. Ka lebaka la tšusumetso ea eona e phahameng le katleho e phahameng, e ka netefatsa ho remahla boleng le ho ntlafatsa katleho ea tlhahiso. Ka indasteri ea elektroniki, handheld laser e ka sebelisoa likarolo tse kopaneng tsa lisebelisoa, tse amanang le litlolo tse ling tsa metjeko ea letsoho, joalo ka lisebelisoa tsa boleng bo holimo. Ntle le moo, li-sheser li ka sebelisoa ka letsoho, joalo ka mesebetsi e nyane e kang ts'ebetso ea mabenyane le ho lokisa li-elektroniki.

Ka nts'etsopele e tsoelang pele ea theknoloji ea Weling ea Laser, Weders ea Laser e tlameletsoe ho ba sesebelisoa sa bohlokoa sa bophelo. Ntle le ho fetoha le maemo Re lumela hore haufinyane haufinyane o tla fumana litlatsetso tsa theknoloji ea laser 'me li tsoele pele ho indastering e mengata.