Kenyelletso: Lilemong tsa morao tjena, tšebeliso ea letsoho la WASHold laser la lepotlane e se e atile haholo indastering e fapaneng. Mechine ena e fana ka tšilafatse le ho fetoha ha lintho tse hlokahalang, e li etsa sesebelisoa sa bohlokoa bakeng sa litsebi tsa mo sebelisoa. Sengoliloeng sena se tla u tataisa hore na u ka sebelisa ka nepo mochini oa Willd Laser ka nepo.

LITLHAKISO TSA BOPHELO: Pele o hlahisa mochini oa ho palama waser o sootho, ho bohlokoa hore u be le polokeho. Apara lisebelisoa tse sireletsang tse loketseng joalo ka likhalase tsa polokeho, liatlana le aprone e meholo. Etsa bonnete ba hore sebaka sa mosebetsi se tletse ka thepa e ngata ebile se hlakile ka lisebelisoa life kapa life tse tukang. Ho bohlokoa hape ho bala le ho utloisisa litaelo tsa moetsi le litataiso tsa polokeho pele u sebelisa.

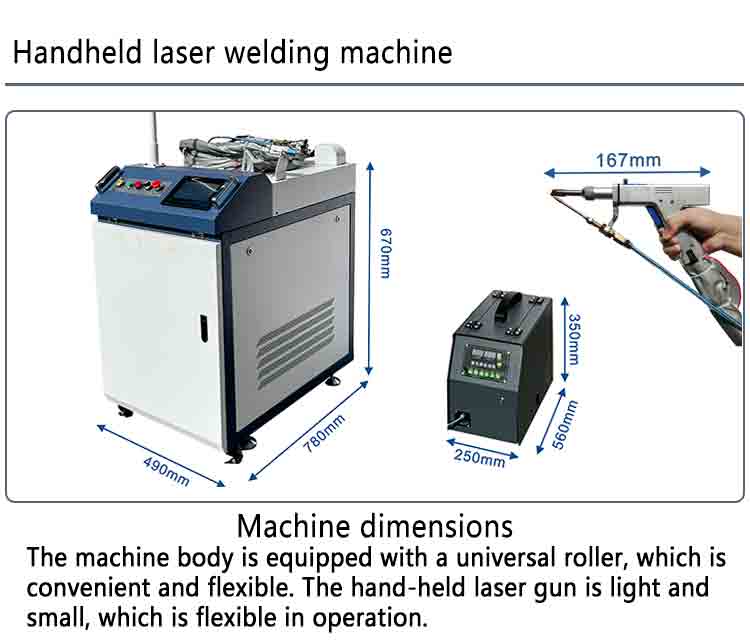

Sethala sa mochini: Qala ka ho khetha likarolo tse loketseng tsa laser tse kang matla a matsoho, li hula hangata, le botenya bo boholo. Sheba bukana ea mochini kapa buisana le setsebi haeba ho hlokahala. Kopanya mochini ho mohloli o tšepahalang oa matla le ho netefatsa khokahano eohle e sireletsehileng. Qala ka ho leka mochini ka sekhechana sa mohlala ho netefatsa hore o sebetsa hantle.

Litokisetso tsa lintho tse bonahalang: Lokisetsa thepa e lokelang ho itšetleha ka ho hloekisa le ho tlosa litšila, mafura kapa mafome. Etsa bonnete ba hore mekhahlelo e kopaneng e tsamaisana hantle le e bonolo. Sebelisa likhetla kapa lits'oants'o tse loketseng ho boloka lisebelisoa ka mokhoa o sireletsehileng sebakeng sa ho qoba ho tsamaea leha e le sefe nakong ea ts'ebetso ea ho bopa. Beha lisebelisoa ka tsela e fanang ka phihlello e hlakileng bakeng sa laser laser.

Mokhoa oa ho sebelisa war o bitsoang laser Tsamaisa lesela laser le mohala o kopaneng ebe o kenya letsoho laser. Tsamaisa mochini ka matlapeng, ho boloka lebelo le feto-fetohang ho netefatsa hore o tšoana. Boloka lam ea laser e shebane le mohopolong, e netefatsa hore ha e khelohe tsela eo u e batlang. Fetola lebelo la motsamao ho fihlela botebo ba ho phatloha bo o batlang le ponahalo eaka.

Boleng ba Weld le tlhahlobo Ela hloko sebopeho sa Weld Bead, botebo ba ho kenella, le ho ba sieo ha polase kapa mapetso leha e le afe. Fetola liparamente tsa Welding ha ho hlokahala ho fihlela liphetho tse lakatsehang. Sebelisa mekhoa e sa senyehang e kang dae e senang matla kapa tlhahlobo ea bonono ho tsebahatsa likoli ka bofokoli. Haeba mafube a fumanoa, sekaseka litekanyetso tsa mongana 'me li etse liphetoho tse nepahetseng bakeng sa litsela tse tlang.

Mehato ea kamorao ea poso: Hang ha ts'ebetso e jang e felile, lumella Weld ho ea fola ka tlhaho. Sebelisa mekhoa e loketseng ea ho futhumatsa haeba e hlokahala. Tlosa slag kapa spatter efe kapa efe e sebelisang brashi ea terata kapa lisebelisoa tse loketseng tsa ho hloekisa. Lekola boleng bo akaretsang ba weld le ho fumana litokiso kapa liphetoho tse hlokahalang. Hopola ho qoba ho qoba mochini oa mochini ebe o e lahla mohloling oa matla o e boloka.

Phetha: Ka ho latela tataiso ena, o ka sebelisa ka nepo mochini oa lihlahla tsa ho tsamaea ka letsoho. Pele, sethala se nepahetseng sa tlhokomelo, boitokisetso ba lintho tsa ho lokisa, le ho sebelisa mokhoa o nepahetseng oa ho sebelisa mokhoa o nepahetseng o tla netefatsa litereke tsa boleng bo holimo. Ka boikoetliso le boiphihlelo, o ka tseba tsebo ea ho sebelisa mochini oa weld laser laser le ho fihlela lipina tse tšepahalang likopo tse fapaneng.

Nako ea poso: Aug-28-2023