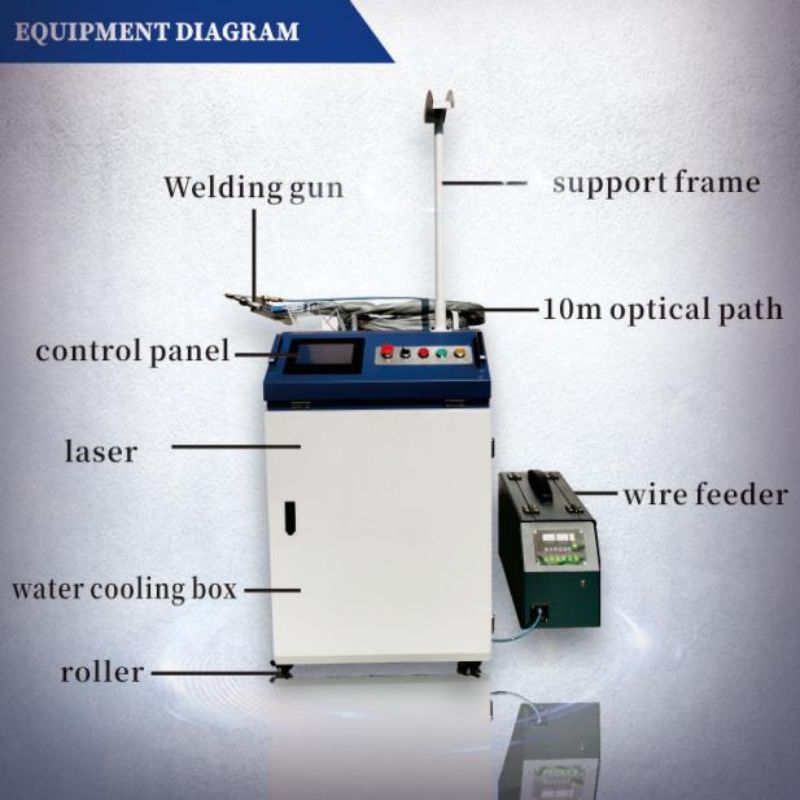

Mochine oa Weld oa laser ke sesebelisoa se sebelisang lam beam ho etsa weld-e ntle haholo. E sebelisa lejoe le phahameng la laser ea matla a phahameng ho kena ka lisebelisoa tsa tšepe hammoho ka nako e khuts'oane haholo. Mechine ea Weser e na le litšobotsi tsa lebelo le potlakileng, letsoalo le phahameng, sebaka se nang le mocheso o mongata o amehang. Mahlale lena ho sebelisoa ho hlahisa koloi, aerospace, lisebelisoa tsa motlakase, lisebelisoa tsa bongaka le indasteri e meng.

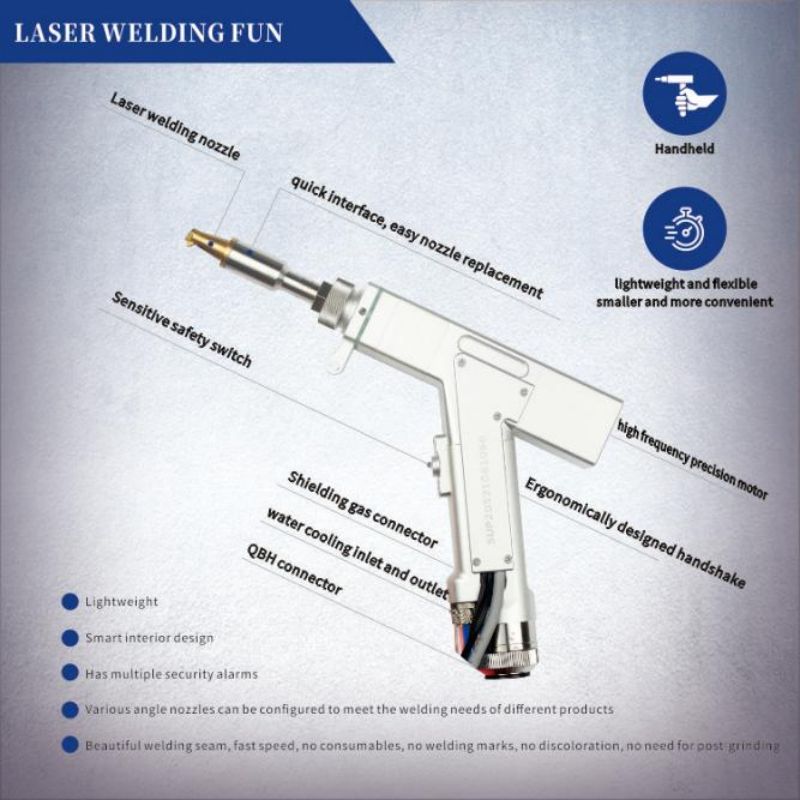

Molao-motheo oa mochini oa laser la laser oa laser ke ho sebelisa lam'ame ea laser ho futhumatsa boitsebiso bo boima. Ka ho laola matla le ho tsepamisa maikutlo ha laser le futhumatsang le ho qhibiliha ka boitsebiso bo fihletsoeng, ka ho etsa joalo ka ho fihlela meea. Ka lebaka la letsoalo le phahameng le khatello ea laser ea laser, mochini oa ho sebelisa litšila o ka khona ho qhibiliha ka potlako le ho qoba ho senya le ho thibela likarolo le tšenyo ea likarolo.

Ntle le moo, mochini oa ho lisala oa laser o ka etsa ts'ebetso ea lintho tse sa kopaneng, 'me o loketse liketsahalo tse nang le litlhokahalo ka lintho tse litsietsing.

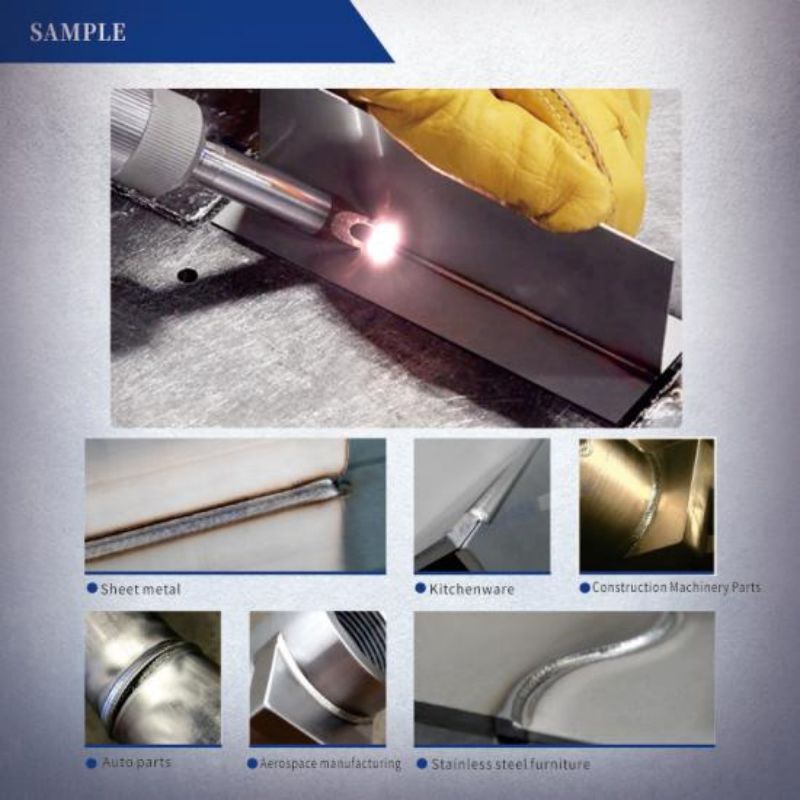

Masimo a kopo ea mechini ea mechini ea laser ho bata haholo. Tšimong ea mochini oa koloi ea chelete e ka sebelisoa ho likarolong tsa 'mele, likarolo tsa enjine, tse ntlafatsang boleng ba WALDING le ho etsa boleng. Tšimong ea Aerospace ea Aerospace, ho ka sebelisoa mochini o boima oa ho senya liaparo, likarolo tsa spacecraft, ho fihlela thepa e phahameng haholo. Tšimong ea lisebelisoa tsa elektroniki le lisebelisoa tsa bongaka tsa laser li ka sebelisoa ho likarolo tse nyane le lisebelisoa tsa ho boloka ho fihlela ho nepahala ha kopo.

Ka kakaretso, ho na le mechini e kenang ka mokhoa o sa feleng le e nepahetseng ka ho hlaka ka tšebeliso e phahameng le e phahameng, e fanang ka lits'ebetso tsa bohlokoa le ts'ebetso ea kopano bakeng sa tlhahiso ea sejoale-joale. Ha Theknoloji ea Laser e ntse e tsoela pele ho ba le mechini e mebileng le e holileng, laser e tla bapala karolo ea bohlokoa indastering ea tlhophisong ea tlhahiso.

Nako ea poso: Jan-22-7244