Ha mekotla e phahameng ea UV e sebelisoa haholo ka ho ngolla thepa e ngata, siliniki e chekiloeng ka ho fetisisa ea siling, e chesang ho khaola boto ea boto ea pele e khaola le masimo a mang a mangata. Ntlafatso e tsoelang pele ea ho ba le mokhathala le katleho, matla le botsitso le botsitso ba UVS li lokela ho ba holimo le ho feta. Maaman Laser o ikemiselitse ho etsa theknoloji ea Laser, haholo-holo tšollo e matla le ea botsitso.

Maimanna Laser Thutong ea botebo ba mantsoe a ultraviolet, a akaretsa likarolo tse tharo tsa botlolo ea letsopa, 'me ka hona uv Laser ka matla a phahameng, boleng bo holimo le botsitso bo phahameng bo ka phethahala.

Matla a phahameng UV, rarolla ka katleho ho rarolla boleng ba matla, 'me ho na le boleng bo phahameng ba beam le botsitso, tšebeliso ea batho ba se nang matšoenyeho

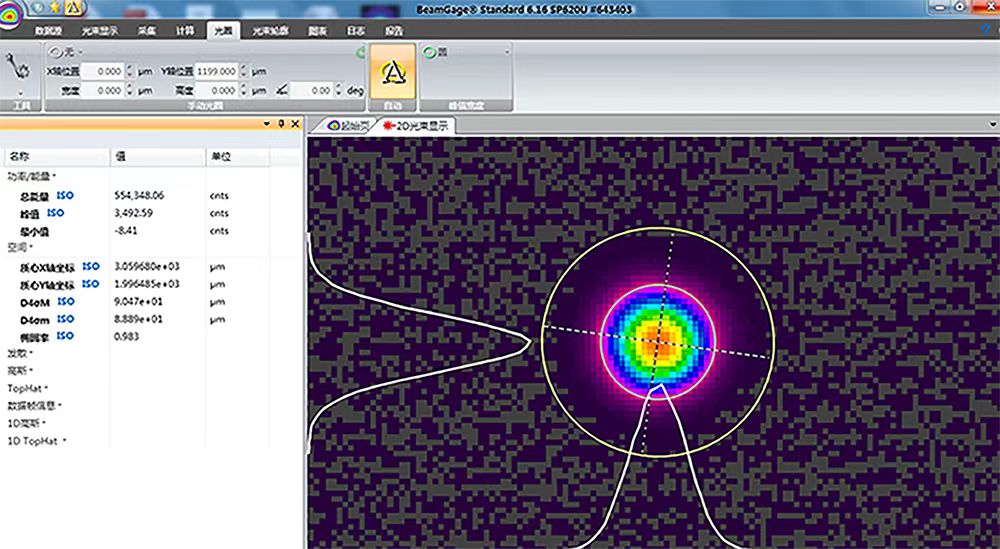

Spot Contour Sygram

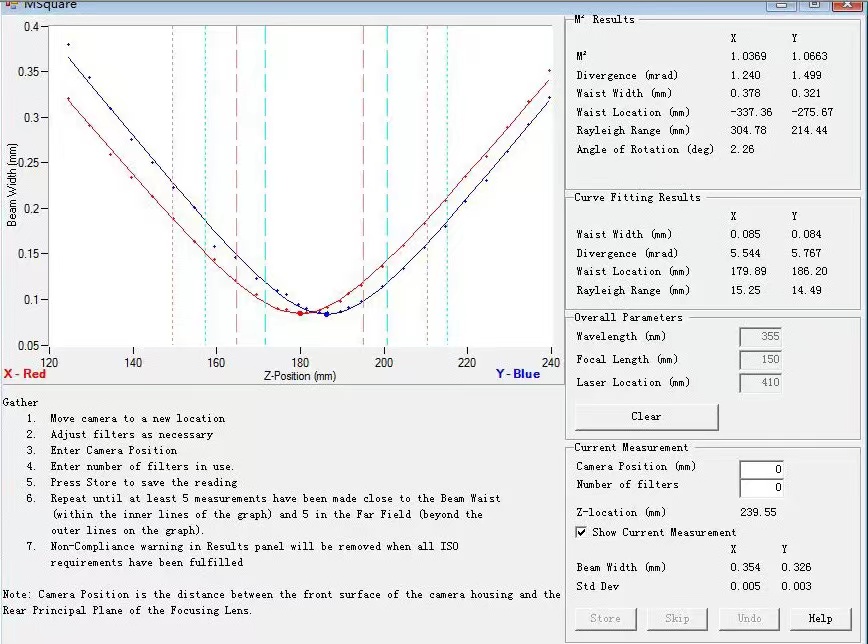

Tebello ea Teko

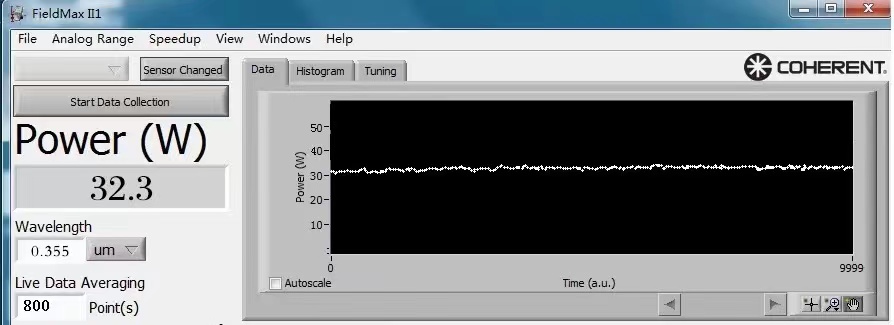

Botsitso ba matla

Ka lebaka la ho futhumatsa laser, Maiman Laser ho moeti oa lapeng oa laser Boleng ba Boam bo ntlafatsoa, bo fanang ka tokelo e matla bakeng sa tlhahiso e phahameng ea UV ea UVS e phahameng ea UVS.

Karolong ea tšenyo ea tšenyo ea khafetsa, Maiser a ile a etsa hore ho be le moea oa matla oa laser ho fokotsa maemo a holimo a UV Laser a le maemong a tšoanang. Ka nako e ts'oanang, mokhoa oa koluoa ea kokoanamo le theknoloji ea metallization ka mokhoa o fumanehang ka har'a li-vutheliles o hlahisoang ka har'a letsopa la li-crystala tse tloaelehileng.

Mabapi le mathata le botsitso ba tsela e telele ba tsela ea pokello ea litheko, ka lebaka la botsitso ba tsela ea molomo, ba thehileng sebopeho sa mochini, bo tsitsitseng ba Ka mokhoa o khethehileng oa ts'ebetso ea ts'ebetso le morero oa phekolo ea mocheso ho fokotsa sebopeho sa boitsebiso bo fapaneng, ho netefatsa botsitso ba nako e telele ba laser.

Maiman a laser ho tloha sethethefatsi se matla sa bo-'ma se matla sa bo-5rnical, se matla se phahameng sa bo-30: Motšehare o mongata, o ka o sebelisa hohle tšimong.

Maiman Laser ka bokhoni bo matla ba bocha, 'marakeng o ne o hapile botumo bo botle le setsi se pharaletseng sa bareki, ho tloha ho ba sa tsebeng ho oela lerabeng la puse

Chuke o tla ithuta ho k'hamphani ea Maman ho etsa mochini o motle ka ho fetisisa le lipalesa tsa boleng bo holimo, 'me lefatše le be le feme ea ho tšoaea.

Nako ea poso: Aug-29-2022