'Marakeng oa mechini e nyane ea Metal oa ho lema o matlafalitse maikutlo a maholo ha likhoebo li batla tharollo e sebetsang le ea ho tšoaea libaka tsa tšepe. Mechini ena e kopaneng empa mechini ena e matla e hlokometse ka lebaka la ho ba le boikarabelo le bokhoni ba ho fana ka matšoao a nepahetseng le a boleng bo holimo. Lilemong tsena tsa ho sebelisana le bokuli, ho kula, ho na le mechini ea ho tšoaea merifo ea meriti ea tšepe ea tšepe e nyane ea ho tšoaea.

E 'ngoe ea melemo ea mantlha ea methapo e nyane ea Metal ea Laser ke litheko tsa tsona tsa tlholisano. Ho fapana le mechini e meholo le ea bulkier, mefuta ena e kopaneng e fana ka tharollo e sebetsang ho likhoebo tse nyane tse ka bang le li-budget tse fokolang. Ka ho fumaneha ha likhetho tse theko e tlaase, esita le ho qala le baetsi ba lisosa tsa senyane joale ba ka tsetela theknoloji ea laser ho tšoaea litlatse.

Mechine e nyane ea meriko ea merinse ea Laser e sebelisa theknoloji e tsoetseng pele ea laser ea Laser e tsoetseng pele ea ho fihlela ka mokhoa o ikhethileng ho feta ho tšoaea mabopong a tšepe. E na le litsamaiso tsa boleng bo holimo le maemo a holimo-bo-ratam, mechine ena e ka hlahisa meralo e hlakileng le e rarahaneng, litemana tsa alphaumeric le logong ka nepo e nepahetseng. Ho nepahala ho tlisa ho tsebiso e ntlafalitsoeng, ho tsoala, le bokuli, ho etsa hore li lokele indasteri e kang ea kokotatho, elektroniki le mabenyane.

Mechine ena e etselitsoe ho tšoaea libaka tsa tšepe tse ngata, ho kenyelletsa le tšepe e se nang letsoai, aluminium, koporo le tse ling. Ka ho fetoha ha bona, mechini ea ho tšoaea metlae ea Mera ea Metal ea Merashe ea Laser e fumana lisebelisoa indastering e fapaneng. Ho tloha ho ngolla libini tsa elektroniki ho kenya merero e rarahaneng ka likotoana tsa mabenyane, likopo li haelloa ke popo ea mosebelisi.

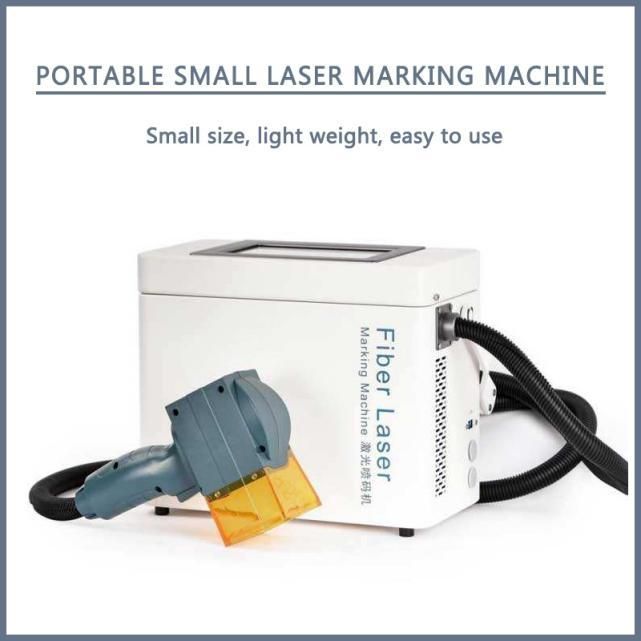

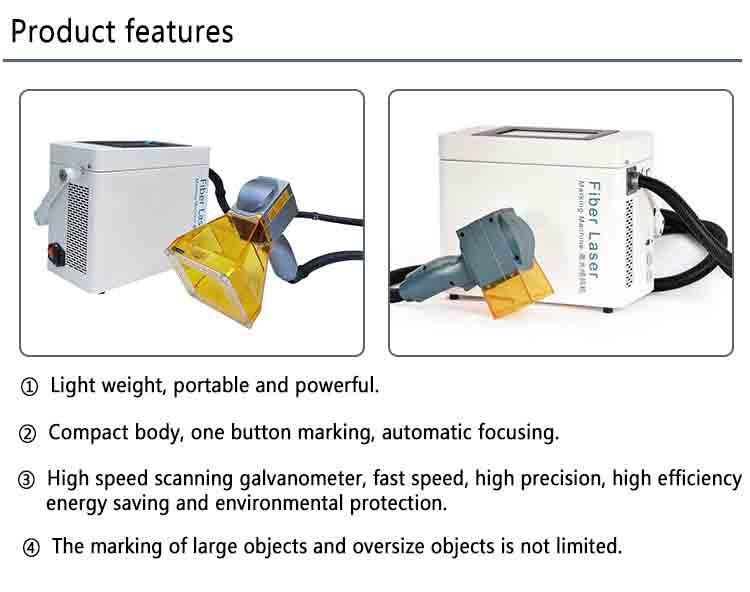

Mechini e nang le metrina e nyane ea ho tšoaea ea Laser e etselitsoe ka kotloloho e hlophiselitsoe ka ho khetheha e hlophiselitsoeng. Boholo ba bona bo nyane bo lumella ho kopana habonolo ho mela e teng ea tlhahiso ntle le ho baka likhatello tse kholo. Ho feta moo, linaha tsa bona tse botsoalle le tsa ho tloaelana li etsa hore ho be bonolo hore ba boloke le lenaneo ho ea ka litlhokahalo tsa bona tsa ho tšoaea. Sena se fokotsa koetliso ea ho ithuta le ho fokotsa nako ea phomolo, ho boloka nako le nako ea nako le chelete bakeng sa likhoebo.

Leha ba sa fella, mechine ena e hlokolosi e thibela metsoako e thata e ka emisang litlhoko tsa tikoloho ea indasteri. Baetsi ba lihlahisoa ba ka itšetleha ka litlhoko tsa bona tse telele tsa boemo ba ho lokisa le ho netefatsa tlhahiso e sa sebetsoang ebile e sebetsa hantle.

Mechini e nang le metjeko ea merifo ea metjeko ea merifo ea tšepe e fetotse tsela eo likhoebo e tšoaeang libaka tsa tšepe. Ka litheko tsa bona tsa tlholisano, ho nepahala ho phahameng, ho senyeha ha moralo, ho sebelisoa moralo, mechini ena e etsa li-areries tsa tsona lefats'eng lohle. Ha theknoloji e ntse e tsoela pele ho qoba ho ntlafatsa le ho ntlafatsa, ho ka ba le mechini ea ho tšoaea metlae ea merila ea Metraver ea Merashe ea Meshu a ho ntlafatsa tlhahiso, bokuli, le katleho e akaretsang ea baetsi.

Nako ea poso: nov-27-1023